Our Process for Underside Rustproofing

Thorough, Longlasting Underseal Protection

Continuing on from the final stage of the pre-treatment preparation process. All preparation and any repairs are complete and we have a clean, dry surface ready to treat.

1. Paintwork Protection

We put protective plastic sheeting over the bodywork to prevent nearly all overspray and mask up anything that shouldn't be painted (such as fancy suspension sets, vents etc). This won't stop all overspray but it'll stop the majority reducing the end cleaning.

2. Undercoat Layer

Initial application of undersealing product over entire underside up to the inner sill edge and the inside lip of each wheel arch. On average this layer takes three or four litres or so of product. We are aiming for a good even all over coverage.

3. Main Coat Layer

Secondary application of undersealing product over entire underside up to the inner sill edge and the inside lip of each wheel arch. On average this layer takes six litres or so of product. The overall effect should be a nice thick black underseal now.

4. Top Coat Layer

Final application of undersealing product over entire underside up to the inner sill edge and the inside lip of each wheel arch. On average this layer takes two or three litres or so of product and should leave the underside thoroughly coated and protected.

5. Cavity Wax Injection

Using our special tooling we inject heated Waxoyl or heated Lanoguard into the cavities. We are aiming for a nice thick coating to stick to cavity surfaces and act as a barrier for water or contaminates. More information about cavity wax injection can be found here.

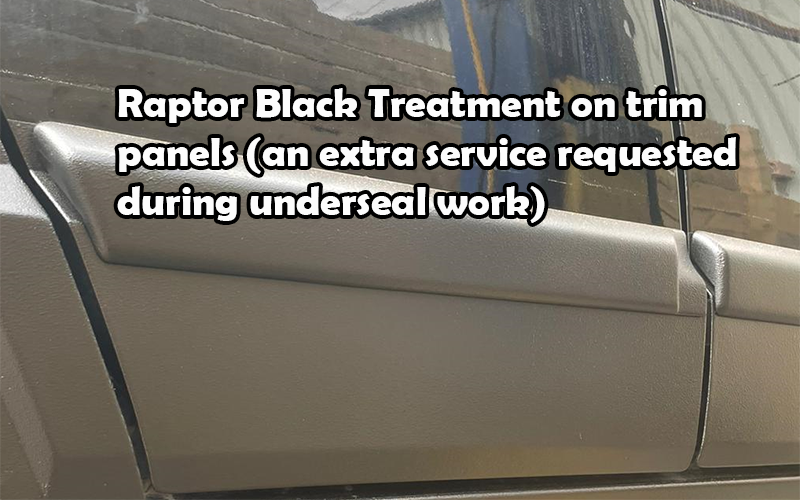

6. Any Extras

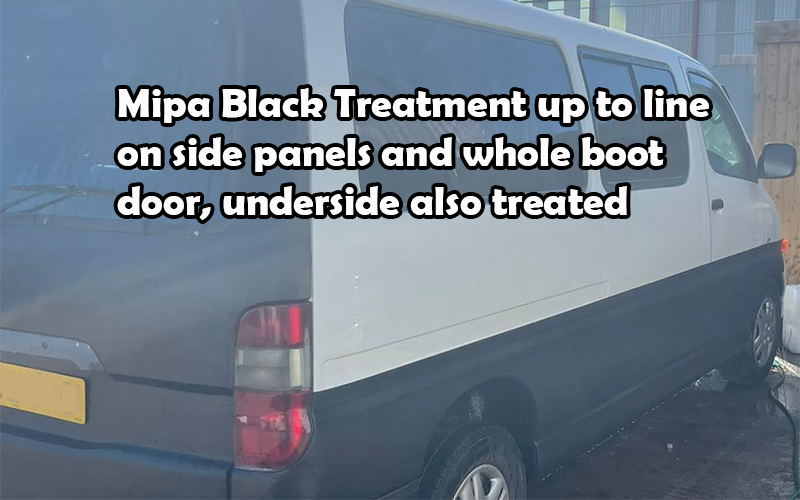

Our treatment process is designed for underside undersealing and protection but sometimes we are asked to treat trims, guards or bumpers or even on occasion outer sills. If we agree to this it is on a best effort basis and the products used will be either Raptor or Stonechip as this is more suitable for outer surfaces.

7. Drying Time

We want the treated areas to be dry before the vehicle is used so we will generally need to leave heat lamps under the vehicle for a couple of hours and keep the vehicle for eight hours or so before collection after the treatment is completed. There are also drying times between each layer of a couple of hours.

8. Quality Control & The Cleanup

Each vehicle undergoes a quality control check from a supervisor or one of the managers to make sure that we are satisfied the treatment is done to our standards and can be warrantied as such. Then all the protective sheeting will be removed and the paintwork checked and cleaned of any small overspray.

9. Paperwork & Hometime

Pictures from throughout the process are downloaded and WhatsApp messaged to the number provided by you for your records. The invoice, warranty certificate and annual inspection book is prepared and printed. Please let us know if you would like the vehicle lifted when you come to collect so we can make sure a ramp is free.

Some Pictures of the Final Finish

A treatment to be proud of, certified & warrantied

"No two vehicles are exactly the same to treat, each one needs the process tweaked here and there to suit the condition and customer choices"

How does the pricing work?

Put simply, the bill you get for the work done on your vehicle is a simple calculation of the labour time spent doing the job plus all the products and consumables used on your car. You receive a breakdown of this on the paperwork too. Obviously until we do the job, we can't be entirely sure how long we will need to spend or how much product will be used.

Labour Time

Labour required to do the job can be affected by several variables including the amount of preparation required on your vehicle, whether repairs are needed, the size of the vehicle, how many undertrays or trims need to be taken off and put back on, how much masking and cleaning is needing, whether you've asked for extras & finally choice of products.

Products & Consumables

Some of the consumables (soap, sand, discs etc) are simply billed on a flat rate per job to cover the cost of these. Similarly when there are repairs there is a flat rate charge to cover the welding gas and sundries. However the products themselves are billed directly from the quantities actually used on your vehicle.

Basic Product Information

Understanding the choice of products

There's so many different products out there, here are some of the ones we use (not all at once obviously) in different combinations depending on what works best for the job in question. If you have a specific request please talk it through with us, we can accomodate your choices as long as what you are asking for can meet our standards for longevity and warranty.

REQUEST OUR FREE BROCHURE

OR POP IN FOR OUR FREE INITIAL ASSESSMENT & PICK ONE UP IN PERSON!

Info Brochure