Treatment quality depends entirely on the preparation!

What's so important about pre-treatment preparation?

Applying the underside rustproofing treatment to a poorly prepared surface is pointless.

The treatment process is designed to be applied onto good metal. Putting the treatment on top of already established rust will simply seal the corrosion under the rustproofing and encourage it to move inwards.

It is necessary to remove any failing factory original underseal where moisture may be stuck underneath.

ContaminatesWhen we refer to cleaning off contaminates, we are talking about mud, dirt, moss, leaves, grass, tar, gravel, silt, salt and just about anything else that could have been got on the underside whilst the vehicle was travelling around or parked up. |

CorrosionCorrosion is of course simply a posh word for rust. We reference corrosion into three stages (more information can be found here) all of which need to be dealt with before we can treat the underside, the longer it's been there, the deeper it goes. |

Factory UndersealMajority of vehicles leave the manufacturer factory with some sort of underseal. Sadly over time the original underseal will degrade (generally we see cracks) and allow water and contaminates to get against the metal. |

Contaminates

Example of Mud & DirtHeavy deposits that have clearly been building up layer on layer like this will need extensive jetwashing to remove

Corrosion

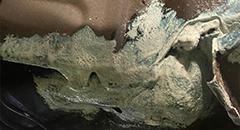

Example of Surface RustStage 2 corrosion with some Stage 3 patches that may be deeper than first assessment. This needs removing and conversion.

Underseal

Example of Failing UndersealIf you look closely at the picture you can see several areas where the original factory underseal (black) has cracked or degraded.

Our Process for Pre-Treatment Preparation

Getting the underside ready

1. Trim Removal

Once on ramp, wheels are removed and any undertrays, arch liners, underside covers or trims are taken off for full access to underside. All parts are labelled, all fixings are lin binned, and both are stored on racking.

2. Initial Jetwash

First Clean. We start with a high pressure cold jetwash to remove worst of the contaminates. This should get rid of mud and debris in particular, if its dried on it can take ages to get it all off. We find any loose corrosion will come off at this point too.

3. Steam Cleaning

Hot Washing! Next we stean clean the underside. This is done to melt any tar based products or oily patches and also to loosen any failing factory original underseal. Similarly if the vehicle has previously been waxoyled or had a substandard treatment elsewhere, this will remove it.

4. Chemical Jetwash

Now that the loose stuff and worst of the contaminates are removed or softened, we coat the underside in traffic film remover and allow it to soak in before more jetwashing. The chemicals should fimish off removing any tar or oil based products and remove any road salt.

5. Abrasive Preparation

Attack that Rust! Time for the tools! We use a combination of wet sand blasting, shot blasting, air needling, air chiselling, grinding and wire brushing to get back to a solid surface underneath. This exposes any holes or pitting and removes any remaining loose metal or damaged underseal.

6. Rust Conversion

By now the underside might be stained rust coloured but it'll be solid metal or exposed holes. We apply a liberal coating of rust converter to the areas where there was any build up of corrosion. This product converts rust into a water-free, protective black surface that seals to stop future formation.

7. RustRepairs (if needed)

Any holes or pitting will need repairs before we can continue the process. We offer a comprehensive range of solutions to provide high quality repairs. Most holes will need patches welded or in more extreme case panels fabricated. More information can be found here.

8. Seam Sealer, Zinc Primer & Red Oxide

A layer of seam sealer will be applied over any repair works and in any areas where the original seam sealer has failed. Repaired areas will also be coated with zinc primer and / or red oxide to prevent oxidisation and rust.

9. Blow & Dry

We use our high pressure air lines to blow through any chassis channels or cavities to make sure any small residual dust or debris are blown out, then we put heat lamps on to dry the underside ready for the treatment applied.

Sometimes we have to repeat bits of the preparation process to get it right

Average time needed for preparation is six hours for Stage 2 underside

Preparation is charged by time taken so this can vary the total price

Basic Product Information

Understanding the choice of products

There's so many different products out there, here are some of the ones we use (not all at once obviously) in different combinations depending on what works best for the job in question. If you have a specific request please talk it through with us, we can accomodate your choices as long as what you are asking for can meet our standards for longevity and warranty.

REQUEST OUR FREE BROCHURE

OR POP IN FOR OUR FREE INITIAL ASSESSMENT & PICK ONE UP IN PERSON!

Get it now