Understanding Welding

Essential for Metalwork Repairs

Picking the best welding process most suited to the job in hand and having a high level of skill in that process is absolute to the quality of the work. Weaker bonding, corrosion of the weld or a complete lack of adhesion can be issues if the wrong person or the wrong process is chosen.

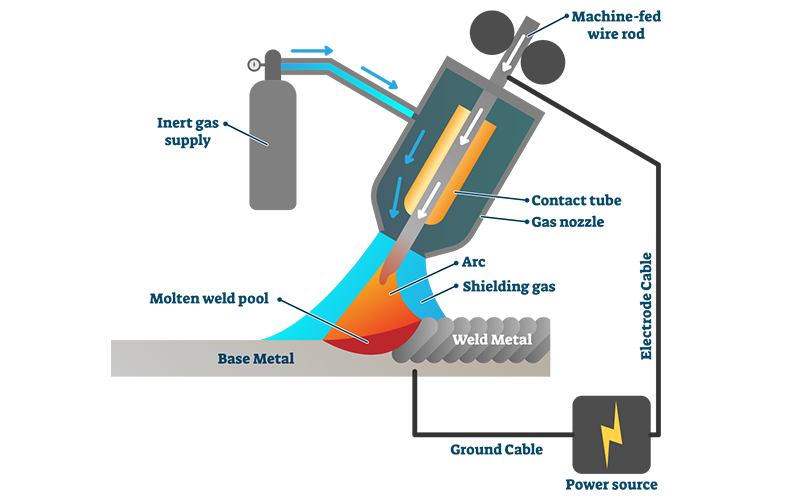

MIG Welding

Metal Inert Gas Welding

Welding wire is fed through the torch with gas and when it meets the tip the wire is melted creating the weld. The continuously fed wire becomes a hot liquid metal filler that fuses two metal surfaces. Generally considered to be the easiest type of welding to learn and master.

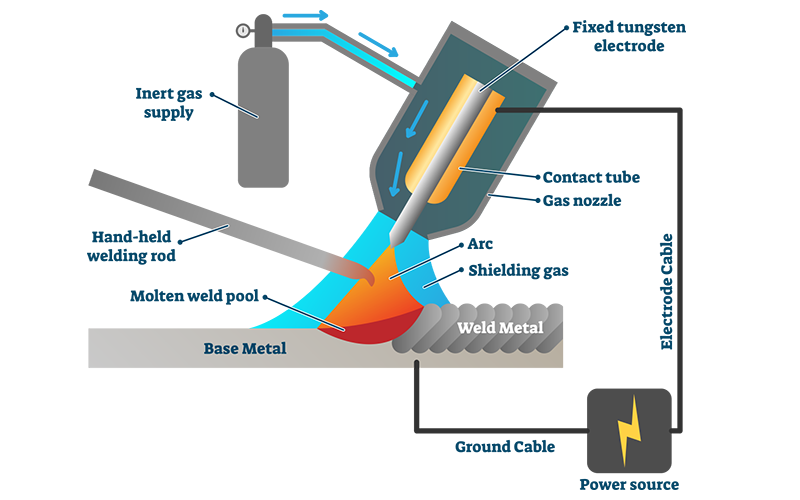

TIG Welding

Tungsten Inert Gas Welding

A very precise skilled welding process needing both hands to dip the welding wire accurately & manually into the arc made by the tungsten electrode forming a single piece of joined metal. If done right, it’s known for the best finish but is known to be hard to master and requires significant skill.

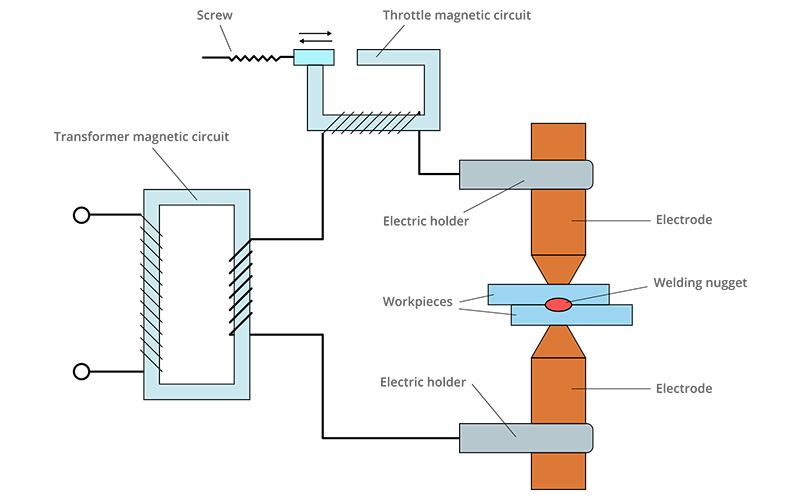

Spot Welding

Resistance Spot Welding

One of the oldest processes, spot welding doesn’t use any filler material. Two or more metal sections are welded together using alloy copper electrodes that pass an electric current through the metal being welded. The metal melts and fuses together between the electrodes.

Welders are like cars!

Understanding the importance of equipment

In the sense that there are lots of makes and models of varying quality and price range, and also from the aspect that what suits one technician may not be right for another. Which is how a workshop starts on the slippery slope of needing not only different types of welder (as above) but also multiple variants of the types!

We have a fine collection of welders (some might say too many....) but here's a little overview of our four main favourites and how they help us achieve the welding standards we insist on.

Fabrication Services

Sometimes you just can't buy it and repairing or making it becomes a necessity

In reality it is rare for damage and degradation to be severe enough that we cannot repair and restore, however in these more severe cases we are most fortunate to have our own in house metalwork facilities for fabrication. With years of expertise and experience we offer a wide range of services in this field as follows.

-

Minor & Major Welding Repairs

-

Installing and / or fabricating replacement sills

-

Repairing Wheel Arch(es)

-

Installing and / or fabricating replacement wheel arch(es)

-

Making a chassis repair section

-

Fabricating or Repairing Floor Panels

-

Making Complex & Unusual Shapes

-

Repairing or Replacing Suspension Mountings

-

Repairing or Replacing Subframes

-

Fabrication of enhanced / improved sections

-

Fabrication of obsolete unobtainable parts / panels

-

Complete light restoration services

Larger scale welding and fabrication work can be costly and take significant time so its not always an option that suits everybody but if the vehicle is worth it to you, we are pleased to offer our skills and high standards to get the job completed. Generally we have a waiting list for this type of work and you may have to wait eight to twelve weeks before we can even fit you into the schedule and get started. Similarly on average larger scale projects can take twelve to twenty four weeks to complete.

Naturally we're talking about a different kettle of fish to the normal everyday rustproofing and rustrepairs we do day in day out. We highly recommend taking advantage of our completely FREE, zero obligation initial assessment or consultation to discuss what you have in mind so we can give you some pricing guidelines based on your individual requirements.

Please also note that we do not provide bodywork paintshop facilities. Majority of our work is based around the underside up to the inner sill edge for example. In cases where we have installed outer sills or arches where "on show" paintwork is needed, we will coat with zinc primer ready for the bodyshop of your choice to do the finishing touches. Sometimes we are asked to apply raptor or stonechip or similar to these "on show" areas, any agreement to do so is strictly under the proviso of it being a best effort basis.

Fabrication Equipment

Understanding the importance of equipment

In order to be able to provide top notch fabrication and metalwork repair services, we've had to collect an assortment of specialist equipment including as follows

REQUEST OUR FREE BROCHURE

OR POP IN FOR OUR FREE INITIAL ASSESSMENT & PICK ONE UP IN PERSON!

Get it now