What Is Shot Blasting?

Using velocity to remove oxidization from metal surfaces

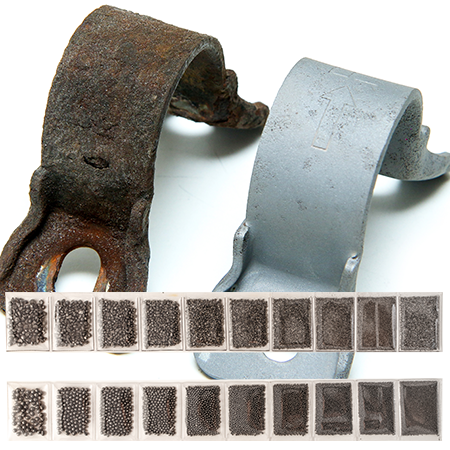

A technique popular for being effective and efficient at removing a build up of contamination (including rust) and changing the texture (how smooth or course) of a metal surface before applying a coating.

If we're being pedantic shot blasting should really only specifically apply to the process when using spherical media rather than the angular grains associated with "Grit Blasting", however since we offer both types of media but do not want to create yet another page dedicated to the same process but with different media, we are not going to be pedantic!

After all shot blasting belongs in the same family as sandblasting and other abrasive blasting processes.

Shot Blasting PotNot always the best option for every vehicle so only used when deemed the right method for the individual case, uses air pressure to blast the surface with media. Often unnecessary for rustproofing preparation where other methods tend to suffice. |

Shot Blasting CabinetWe also have a blasting cabinet which we find is ideal for smaller trims, automotive components including carburettors, rocker covers etc, and anything where the surface needs deeper surface preparation before painting or treating. |

Shot Blasting MediaGlass bead is a versatile media that ticks all the boxes whilst being a lot less hazardous to work with than the traditional sand grit. Less aggressive, no free silica and enviromentally friendly, this produces uniform results. |

How does the pricing work?

Put simply, the bill you get for the work done on your vehicle or component is a simple calculation of the labour time spent doing the job plus all the products and consumables used to do the work. You receive a breakdown of this on the paperwork too. Obviously until we do the job, we can't be entirely sure how long we will need to spend or how much product will be used.

Labour Time

Labour required to do the job can be affected by several variables including the amount of preparation required on your vehicle or item, whether additional repairs are needed, the size of the vehicle or component, how many undertrays or trims need to be taken off and put back on in the scenario of a vehicle, whether the item or component is already off or if we need to remove it to do the treatment.

Products & Consumables

Some of the consumables (soap, glass beads, discs etc) are simply billed on a flat rate per job to cover the cost of these. Similarly there is a flat rate charge to cover electric, water and sundries. However often the products themselves are billed directly from the quantities actually used in your case.

Timescale

Time needed to complete shot blasting works depends on many variables! If we are blasting a whole underside this is likely to be 2 days work not including prior prep or post treatment. Smaller cabinet jobs can often be done whilst you wait if you've already removed the part or trim. It's best to speak to us on a case by case basis to determine timescale.

Warranty

We take a great deal of pride in our workmanship and we guarantee all our processes including shot blasting work will be of the highest standard. All our workmanship gets afforded our fully comprehensive warranty. We provide a certificate of this warranty with each job. If you have any questions about this, just ask away and we can explain further.

" Pricing can be quite varied for this type of work and we ideally need to see the job to give any kind of accurate estimate but as a very rough guide we would say that to glass bead blast the underside and chassis of a small family car (BMW 3 Series for example) would cost in the region of £750. Blasting a rocker cover or carburrettor in the blast cabinet would be in the region of £50 - £150. "

REQUEST OUR FREE BROCHURE

OR POP IN FOR OUR FREE INITIAL ASSESSMENT & PICK ONE UP IN PERSON!

Info Brochure