What Is Vapour Blasting?

Also known as Aqua Blasting; using the power of water to blast surfaces

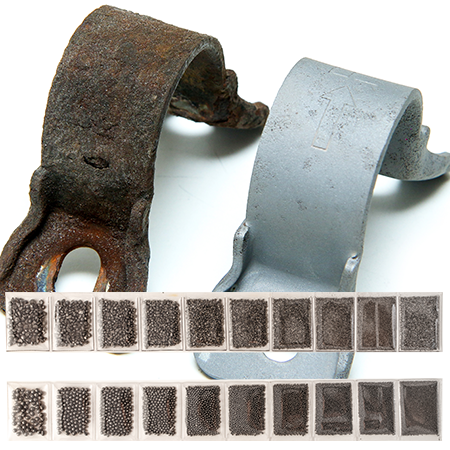

Vapour blasting (also known as Aqua Blasting and sometimes as slurry blasting) is a superior choice for cleaning and restoring vehicle components cleaned to a high standard. Known for being gentle enough not to destroy special markings but leaves a very presentable surface ready for paintwork or finishing touches.

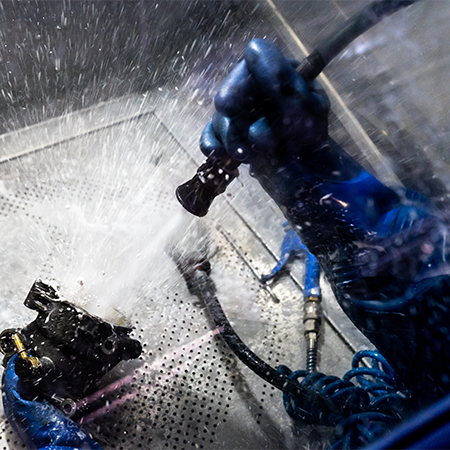

Vapour blasting requires a cabinet to complete the process so this limits the maximum size of item we can treat using this method. We can do most engine casings, carburettors, trims, engine components etc. Inside the cabinet compressed air blasts a high-pressure mixture of water and tiny glass bead media (often referred to as “slurry”) at the item. This process removes all contaminates and old paint leaving a polished fancy finish from the glass beads bombarding the surface.

Aqua Blasting CabinetWe also have a vapour blasting cabinet which we find is ideal for smaller trims, automotive components including carburettors, rocker covers etc, and anything where the surface needs refined surface treatment. |

Shot Blasting MediaGlass bead is a versatile media that ticks all the boxes whilst being a lot less hazardous to work with than the traditional sand grit. Less aggressive, no free silica and enviromentally friendly, this produces uniform results. |

How does the pricing work?

Put simply, the bill you get for the work done on your component or item is a simple calculation of the labour time spent doing the job plus all the products and consumables used in the process. You receive a breakdown of this on the paperwork too. Obviously until we do the job, we can't be entirely sure how long we will need to spend or how much product will be used.

Labour Time

Labour required to do the job can be affected by several variables including whether the component or item is delivered pre-removed or if we have to remove it ready for the treatment, the size of the item and how long it takes to achieve the required finish.

Products & Consumables

Some of the consumables (soap, water, glass beads etc) are simply billed on a flat rate per job to cover the cost of these. Similarly there is a small flat rate charge to cover the electricity and sundries. However sometimes on larger items it is necessary for the products to be billed directly from the quantities actually used.

Timescale

Time needed to complete vapour blasting works depends on many variables! If we are blasting a big item this is likely to be 4 - 5 hours work not including prior prep or post treatment. Smaller jobs can often be done whilst you wait if you've already removed the part or trim. It's best to speak to us on a case by case basis to determine timescale.

Warranty

We take a great deal of pride in our workmanship and we guarantee all our processes including aqua blasting work will be of the highest standard. All our workmanship gets afforded our fully comprehensive warranty. We provide a certificate of this warranty with each job. If you have any questions about this, just ask away and we can explain further.

" Pricing can be quite varied for this type of work and we ideally need to see the job to give any kind of accurate estimate but as a very rough guide we would say that to vapour blast a single carburettor would cost in the region of £50 - £100 and take about and hour or two. Blasting a rocker cover would be in the region of £100 - £150. "

REQUEST OUR FREE BROCHURE

OR POP IN FOR OUR FREE INITIAL ASSESSMENT & PICK ONE UP IN PERSON!

Info Brochure